Permanent Magnet Maximum Working Temperature

Permanent magnets are widely applied in various motors, sensors/instruments and electronics, their temperatures almost vary more or less during work. These temperature variations are resulted from eddy current effect and/or ambient temperature variation. Due to thermal fluctuation and magnetic domain evolution, a permanent magnet loses some or all magnetic flux when its temperature elevates. Here comes a question, how high temperature can a permanent magnet withstand to work? For a commercial permanent magnet, the upper temperature limit is called maximum working temperature.

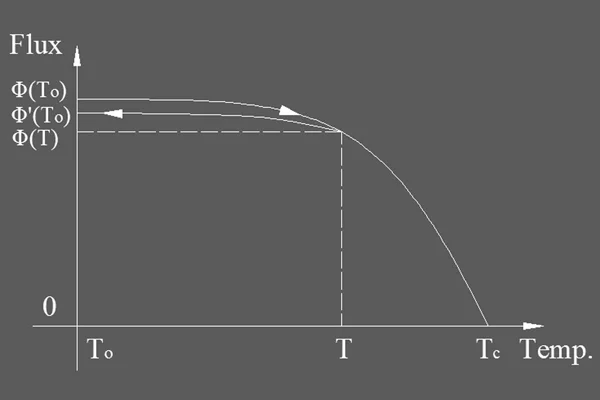

In both fields of theory and application, the temperature elevation dependent flux loss is commonly divided into two parts, i.e. reversible flux loss and irreversible flux loss. The reversible flux loss is able to recover at original temperature when a permanent magnet cools down from elevated temperature, while the irreversible flux loss is unable to recover. These two parts can be calculated by the two formulas as below, respectively.

hrev = [Φ’(To) - Φ(T)]/Φ’(To)×100% (1)

hirr = [Φ(To) - Φ’(To)]/Φ(To)×100% (2)

where hrev is reversible flux loss percentage,

hirr is irreversible flux loss percentage,

Φ(To) is original magnetic flux at original temperature To,

Φ’(To) is magnetic flux at original temperature To when a permanent magnet cools down from elevated temperature T,

Φ(T) is magnetic flux at elevated temperature T.

Actually hirr is a more useful parameter in application. In the market, most customers generally accept hirr smaller than 5% after thermal aging or cycling, so maximum working temperature is the threshold when a permanent magnet reaches hirr(≤ 5%). Besides, some customers require hirr smaller than 3%. And a few customers even require little irreversible flux loss, in that case the required permanent magnet should be supplied by stabilization treatment at elevated temperature higher than its maximum working temperature.

In most applications, permanent magnets work in open circuit. Researches show that a permanent magnet’s irreversible flux loss is not only related to its composition and microstructure, but also related to its shape. So is maximum working temperature. A permanent magnet’s composition and microstructure determine its magnetic properties, i.e. grade. For grading comparison, a standard sample shape is fixed (an axially magnetized cylinder with diameter 10 mm and length 7 mm or permeance coefficient (Pc) = 2), then its maximum working temperature depends on its grade. For sintered neodymium iron boron (NdFeB) magnet, -H, -SH and -UH grades’ maximum working temperatures are 120, 150 and 180 degrees Celsius, respectively. For sintered 2:17 type samarium cobalt (Sm2Co17) magnet, -L, -M and -H grades’ maximum working temperatures are 250, 300 and 350 degrees Celsius, respectively. As maximum working temperature classified by grade is based on default Pc = 2, it should do more test for grade/material selection in practical case. Take sintered NdFeB magnet for example, if the designed Pc is lower than 2 and its required maximum working temperature is 150 degree Celsius, -UH grade may be suitable for it instead of -SH grade. Or if the designed Pc is higher than 2 and its required maximum working temperature is 120 degree Celsius, -M grade may be feasible to replace -H grade.