Sintered SmCo magnets, i.e. sintered samarium cobalt magnets, are those permanent magnetic materials that based on a hexagonal crystal structure (1:5 type SmCo magnets) or a rhombohedral crystal structure (2:17 type SmCo magnets), and they are manufactured through a powder metallurgy process. They contain two basic elements samarium and cobalt. The samarium element can be substituted by a portion of other rare earth elements including praseodymium (Pr), cerium (Ce), gadolinium (Gd), erbium (Er), etc. The cobalt element can be substituted by a portion of iron (Fe) element to increase the magnets’ saturation magnetization (Ms). In order to control the microstructure and the microchemistry so as to meet required performance, it is also critical to add a small portion of copper (Cu), zirconium (Zr), titanium (Ti), etc. According to crystal structure, samarium cobalt magnets include SmCo5 magnets (1st generation of REPMs) and Sm2Co17 magnets (2nd generation of REPMs). They were invented/developed by K. Strnat’s team in the 1960s and T. Ojima’s team in the 1970s, respectively. Due to their high Curie temperature (Tc: 700-850 ºC), middle high maximum energy product ((BH)max: 110-260 kJ/m3), low temperature coefficients of remanence (α(Br): +0.01 to -0.05 %/°C) and coercivity (β(Hcj): -0.2 to -0.3 %/°C) and high corrosion resistance, sintered SmCo magnets are mainly applied in high temperature motors, servo motors, stepper/stepping motors, traveling wave tubes (TWTs), circulators, isolators, klystrons, undulators, gyroscopes, accelerometers, instruments and meters, etc.

Sintered SmCo magnets, i.e. sintered samarium cobalt magnets, are those permanent magnetic materials that based on a hexagonal crystal structure (1:5 type SmCo magnets) or a rhombohedral crystal structure (2:17 type SmCo magnets), and they are manufactured through a powder metallurgy process. They contain two basic elements samarium and cobalt. The samarium element can be substituted by a portion of other rare earth elements including praseodymium (Pr), cerium (Ce), gadolinium (Gd), erbium (Er), etc. The cobalt element can be substituted by a portion of iron (Fe) element to increase the magnets’ saturation magnetization (Ms). In order to control the microstructure and the microchemistry so as to meet required performance, it is also critical to add a small portion of copper (Cu), zirconium (Zr), titanium (Ti), etc. According to crystal structure, samarium cobalt magnets include SmCo5 magnets (1st generation of REPMs) and Sm2Co17 magnets (2nd generation of REPMs). They were invented/developed by K. Strnat’s team in the 1960s and T. Ojima’s team in the 1970s, respectively. Due to their high Curie temperature (Tc: 700-850 ºC), middle high maximum energy product ((BH)max: 110-260 kJ/m3), low temperature coefficients of remanence (α(Br): +0.01 to -0.05 %/°C) and coercivity (β(Hcj): -0.2 to -0.3 %/°C) and high corrosion resistance, sintered SmCo magnets are mainly applied in high temperature motors, servo motors, stepper/stepping motors, traveling wave tubes (TWTs), circulators, isolators, klystrons, undulators, gyroscopes, accelerometers, instruments and meters, etc.

Sintered SmCo Magnets’ Grades and Their Magnetic Properties

| Grade | Br | Hcb | Hcj | (BH)max | Tw | ||||

|---|---|---|---|---|---|---|---|---|---|

| kGs | T | kOe | kA/m | kOe | kA/m | MGOe | kJ/m3 | ºC | |

| XGS32H | 11.0-11.5 | 1.10-1.15 | ≥10.2 | ≥812 | ≥25 | ≥1990 | 30-32 | 239-255 | ≤350 |

| XGS30H | 10.7-11.2 | 1.07-1.12 | ≥9.9 | ≥788 | 28-30 | 223-239 | |||

| XGS28H | 10.4-10.9 | 1.04-1.09 | ≥9.6 | ≥764 | 26-28 | 207-223 | |||

| XGS26H | 10.0-10.5 | 1.00-1.05 | ≥9.2 | ≥732 | 24-26 | 191-207 | |||

| XGS24H | 9.7-10.2 | 0.97-1.02 | ≥8.9 | ≥708 | 22-24 | 175-191 | |||

| XGS22H | 9.3-9.8 | 0.93-0.98 | ≥8.5 | ≥676 | 20-22 | 159-175 | |||

| XGS20H | 9.0-9.5 | 0.90-0.95 | ≥8.2 | ≥653 | 18-20 | 143-159 | |||

| XGS32 | 11.0-11.5 | 1.10-1.15 | ≥10.0 | ≥796 | ≥18 | ≥1433 | 30-32 | 239-255 | ≤300 |

| XGS30 | 10.7-11.2 | 1.07-1.12 | ≥9.7 | ≥772 | 28-30 | 223-239 | |||

| XGS28 | 10.4-10.9 | 1.04-1.09 | ≥9.4 | ≥748 | 26-28 | 207-223 | |||

| XGS26 | 10.0-10.5 | 1.00-1.05 | ≥9.0 | ≥716 | 24-26 | 191-207 | |||

| XGS24 | 9.7-10.2 | 0.97-1.02 | ≥8.7 | ≥692 | 22-24 | 175-191 | |||

| XGS22 | 9.3-9.8 | 0.93-0.98 | ≥8.3 | ≥660 | 20-22 | 159-175 | |||

| XGS20 | 9.0-9.5 | 0.90-0.95 | ≥8.0 | ≥637 | 18-20 | 143-159 | |||

| XGS32M | 11.0-11.5 | 1.10-1.15 | ≥9.0 | ≥716 | ≥12 | ≥955 | 30-32 | 239-255 | ≤300 |

| XGS30M | 10.7-11.2 | 1.07-1.12 | ≥8.7 | ≥692 | 28-30 | 223-239 | |||

| XGS28M | 10.4-10.9 | 1.04-1.09 | ≥8.5 | ≥676 | 26-28 | 207-223 | |||

| XGS26M | 10.0-10.5 | 1.00-1.05 | ≥8.5 | ≥676 | 24-26 | 191-207 | |||

| XGS24M | 9.7-10.2 | 0.97-1.02 | ≥8.5 | ≥676 | 22-24 | 175-191 | |||

| XGS22M | 9.3-9.8 | 0.93-0.98 | ≥8.2 | ≥653 | 20-22 | 159-175 | |||

| XGS20M | 9.0-9.5 | 0.90-0.95 | ≥8.0 | ≥637 | 18-20 | 143-159 | |||

| XGS32L | 11.0-11.5 | 1.10-1.15 | ≥6.8 | ≥541 | ≥8 | ≥636 | 30-32 | 239-255 | ≤250 |

| XGS30L | 10.7-11.2 | 1.07-1.12 | ≥6.8 | ≥541 | 28-30 | 223-239 | |||

| XGS28L | 10.4-10.9 | 1.04-1.09 | ≥6.6 | ≥525 | 26-28 | 207-223 | |||

| XGS26L | 10.0-10.5 | 1.00-1.05 | ≥6.6 | ≥525 | 24-26 | 191-207 | |||

| XGS24L | 9.7-10.2 | 0.97-1.02 | ≥6.5 | ≥517 | 22-24 | 175-191 | |||

| XGS22L | 9.3-9.8 | 0.93-0.98 | ≥6.5 | ≥517 | 20-22 | 159-175 | |||

| XGS20L | 9.0-9.5 | 0.90-0.95 | ≥6.5 | ≥517 | 18-20 | 143-159 | |||

| XGS24LT | 9.7-10.2 | 0.97-1.02 | ≥8.7 | ≥692 | ≥18 | ≥1433 | 22-24 | 175-191 | ≤300 |

| XGS22LT | 9.3-9.8 | 0.93-0.98 | ≥8.3 | ≥660 | 20-22 | 159-175 | |||

| XGS20LT | 9.0-9.5 | 0.90-0.95 | ≥8.0 | ≥637 | 18-20 | 143-159 | |||

| XGS18LT | 8.5-9.0 | 0.85-0.90 | ≥7.5 | ≥597 | 16-18 | 127-143 | |||

| XGS16LT | 8.0-8.5 | 0.80-0.85 | ≥7.0 | ≥557 | 14-16 | 111-127 | |||

| XGS14LT | 7.5-8.0 | 0.75-0.80 | ≥6.5 | ≥517 | 12-14 | 95-111 | |||

| XG24H | 9.7-10.2 | 0.97-1.02 | ≥9.2 | ≥730 | ≥23 | ≥1830 | 22-24 | 175-191 | ≤250 |

| XG22H | 9.3-9.8 | 0.93-0.98 | ≥8.8 | ≥700 | 20-22 | 159-175 | |||

| XG20H | 9.0-9.5 | 0.90-0.95 | ≥8.5 | ≥676 | 18-20 | 143-159 | |||

| XG18H | 8.5-9.0 | 0.85-0.90 | ≥8.2 | ≥653 | 16-18 | 127-143 | |||

| XG16H | 8.0-8.5 | 0.80-0.85 | ≥7.8 | ≥620 | 14-16 | 111-127 | |||

| XG24 | 9.7-10.2 | 0.97-1.02 | ≥9.2 | ≥730 | ≥15 | ≥1194 | 22-24 | 175-191 | ≤250 |

| XG22 | 9.3-9.8 | 0.93-0.98 | ≥8.8 | ≥700 | 20-22 | 159-175 | |||

| XG20 | 9.0-9.5 | 0.90-0.95 | ≥8.5 | ≥676 | 18-20 | 143-159 | |||

| XG18 | 8.5-9.0 | 0.85-0.90 | ≥8.2 | ≥653 | 16-18 | 127-143 | |||

| XG16 | 8.0-8.5 | 0.80-0.85 | ≥7.8 | ≥620 | 14-16 | 111-127 | |||

Note:

∗ The data in the above table were samples’ results tested at the temperature of 20 °C.

∗ The prefixes XGS and XG are for Sm2Co17 and SmCo5 magnets, respectively.

∗ The typical temperature coefficients of Br and Hcj are α(Br): -0.03~-0.05 %/ºC and β(Hcj): -0.20~-0.30 %/ºC, respectively.

∗ The suffix LT means low/near-zero temperature coefficient of Br (α(Br): +0.01 ~ -0.03 %/°C).

∗ The above data are only for reference, magnets can be tailored according to customers’ personalized requirements.

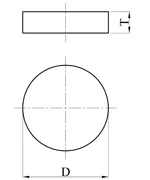

Sintered SmCo Magnets’ Shapes, Magnetization Direction and Size Range

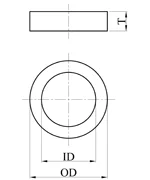

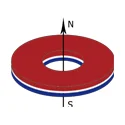

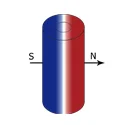

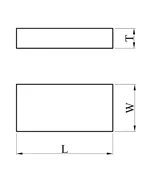

| Shape | Graphic Description | Magnetization Direction | Size Range | |

| Disc/Cylinder Magnet |  |  | Axially Magnetized | D: 1-100 mm |

| T: 0.5-100 mm | ||||

| Diametrically Magnetized | D: 1-100 mm | ||

| T: 0.5-100 mm | ||||

| Ring Magnet |  |  | Axially Magnetized | OD: 5-100 mm |

| ID: 1-90 mm | ||||

| T: 1-60 mm | ||||

| Diametrically Magnetized | OD: 5-100 mm | ||

| ID: 1-90 mm | ||||

| T: 1-60 mm | ||||

| Block/Rectangular Magnet |  |  | Thickness Magnetized | L: 1-160 mm |

| W: 1-100 mm | ||||

| T: 1-100 mm | ||||

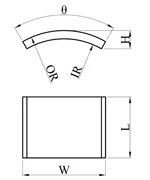

| Arc/Segment Magnet |  |  | Diametrically Magnetized | OD-ID≥1 mm |

| L: 1-120 mm | ||||

| W: 3-100 mm | ||||

| H: 1-60 mm | ||||

Note:

∗ Other shapes of sintered SmCo magnets can also be tailored according to customers’ specific requirements.

Because of strong corrosion resistance, sintered SmCo magnets usually do not need any coating. If any coating is required, nickel, zinc, tin, epoxy, Teflon and other types are available.

Sintered SmCo Magnets Physical Properties

| Parameter | Unit | Value |

|---|---|---|

| Density (ρ) | g/cm3 | 8.2-8.4 |

| Curie Temperature (Tc) | ºC | 700-850 |

| Recoil Permeability (μrec) | - | 1.05-1.10 |

| Vickers Hardness (HV) | MPa | 400-600 |

| Bending Strength (σbb) | MPa | 150-180 |

| Compressive Strenght (σbc) | MPa | 800-1000 |

| Tensile Strength (σb) | MPa | 35-40 |

| Resistivity (ρ) | μΩ·m | 0.5-0.9 |

| Thermal Expansivity ∥ Magnetization (α∥) | 10-6/ºC | 5-9 |

| Thermal Expansivity ⊥ Magnetization (α⊥) | 10-6/ºC | 10-13 |

Note:

∗ The above data are only for reference, specific magnets maybe have different values.