Sintered NdFeB Magnet Composition

Sintered NdFeB magnet contains three essential elements: rare earth neodymium, iron and boron. Nd atoms, coupling with ferromagnetic Fe atoms, help the magnet obtain high remanence Br and maximum energy product (BH)max, which makes it extraordinary compared with other permanent magnets. Although B element has only around 1 wt% in the magnet, it is necessary for the intermetallic phase stability, so the magnet has stable magnetic properties.

In commercial sintered NdFeB magnet, Nd element is usually partially substituted by other rare earth elements including praseodymium, dysprosium and terbium, etc. Because Nd and Pr elements usually coexist in ore and these two elements have similar physical and chemical properties, so it is more economic to produce PrNd alloy instead of pure Nd metal from ore and to use PrNd alloy as the raw material of magnet. As the Nd/Pr ratio in ore is around 4:1, so it is also around 4:1 in most commercial magnets. Dy and/or Tb element substitution for Nd element can remarkably increase the intrinsic coercivity Hcj or Hci due to their higher magnetocrystalline anisotropy field HA. The total content of Dy and Tb elements in the magnet is usually less than 10 wt% because of high cost and Br loss. In general, the total rare earth element content is around 30 wt% in the magnet, and its material cost accounts for around 70% of the magnet or even higher depending on specific rare earth element prices and contents.

Fe element can be substituted by some Co element to enhance the magnet thermal stability and corrosion resistance. Besides, a small amount of Al and Cu elements can be added to improve the magnet microstructure homogeneity to obtain higher Hcj and (BH)max.

Sintered NdFeB Magnet Microstructure

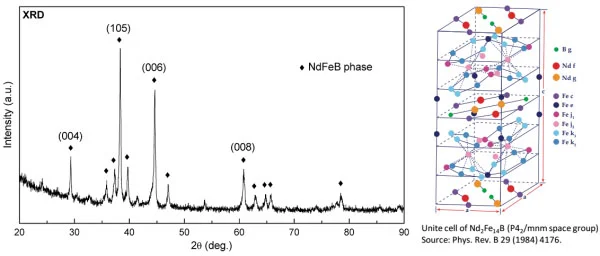

Sintered NdFeB magnet XRD spectrum shows the Nd2Fe14B tetragonal phase is the main phase in the magnet.

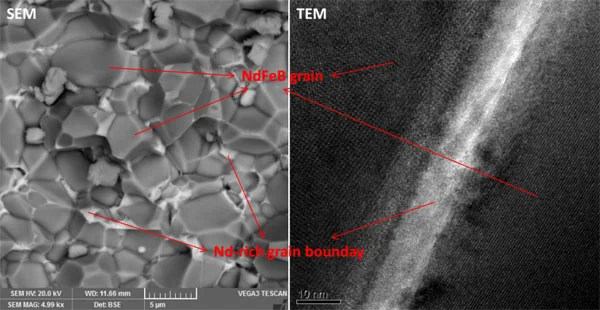

In view of the scanning electron microscope (SEM) image, the darker gray areas are Nd2Fe14B grains, the average grain size is around 6-8 μm. The lighter gray areas surrounding the grains are Ni-rich grain boundaries, the average grain boundary thickness between adjacent grains is around 10 nm as shown in the transmission electron microscope (TEM) image.

In fact, the sintering process of sintered NdFeB magnet is a liquid phase sintering process. The grain boundary phase, with lower melting point than that of grain phase, will melt into liquid phase during sintering process and subsequent annealing process, it is vital to densify the magnet and improve its microstructure homogeneity for enhancing its magnetic properties.

May I use your figure in a Intermag presentation next week, citing the source ?

https://www.advancedmagnets.com/introduction-to-basic-composition-and-microstructure-of-sintered-ndfeb-magnet/

No problem, you can cite it. Thanks for letting us know.